Performance of conventional long-distance reflective photoelectric sensors is not always stable since their detection performance varies with the colors and shapes of detected objects. With its unique sensing algorithm, E3AS-HF has overcome the problem, eliminating the time and effort to select and set up sensors.

E3AS-HF Series

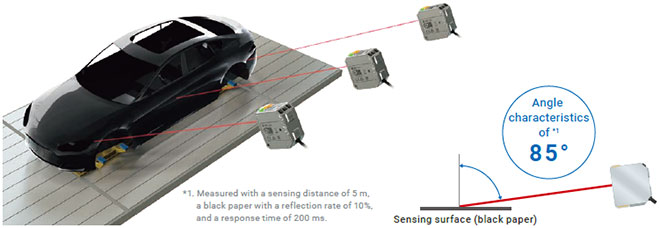

1. A wide sensing range and excellent angle characteristics supported at the same time

A sensing range of 0.05 to 6 m and angle characteristics of ±85° max.

Place the sensors away from the pathways of people and robots so that the sensors do not obstruct their movement.

Thus remove failure risks such as optical axis displacement and cable disconnection due to collision with a workpiece, and ensure stable sensing when the target workpiece is changed or added.

Sensing whether a painted vehicle body is positioned in place

The sensors perform reliable detection even when installed at an angle in a far place or when detecting glossy workpieces with a low-reflective color like black or blue.

Detecting glossy black workpieces at a wide angle

Angle characteristics of 85° max.

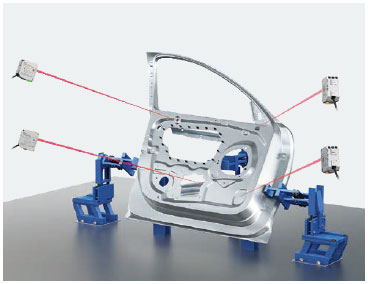

Identifying the vehicle model from the body panel

By detecting the holes and pins of the body panel set on the jig, the sensors identify the vehicle model and detect the presence of necessary parts.

The sensors with excellent angle characteristics can be installed away from the pathways of people and robots.

Detecting a small bore with the spot beam type

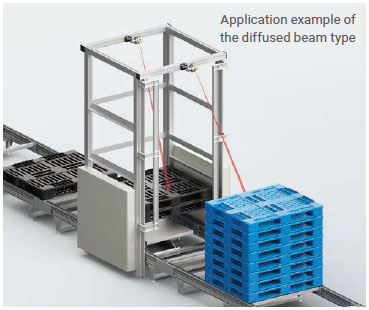

Sensing workpieces in a palletizing process

Multi-color, low-reflective workpieces can be detected reliably. The setup can reduce installation and wiring work compared with through-beam sensors.

Detecting multicolor, low-reflective workpieces

Three technologies underlying the excellent sensing performance

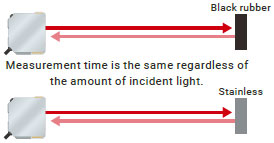

TOF method to stably detect various workpieces

The TOF (Time of Flight) method measures the distance based on the elapsed time. Therefore, measurement is not easily affected by changes in the color and material of the workpieces. The method needs only a low incident light level to perform sensing, so the sensor can detect low-reflective workpieces such as black rubber from a distance.

Operating principle of TOF

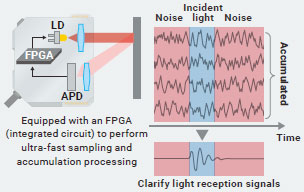

Ultra-fast sampling and unique accumulation processing [PATENTED]*2

By accumulating approximately 10 million data points obtained by ultra-fast sampling at 10 billion times per second, the method obtains a clear incident light waveform and minimizes the noise, enabling stable sensing with a low light level.

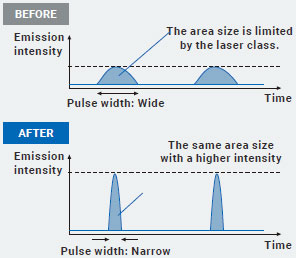

Laser class 1 for safety

Combining as strong an emission as possible within the class 1 limit with the advanced device and high-frequency circuit design technology, the sensor can perform laser control within an extremely narrow pulse width.

This reduces the need for operator safety measures and equipment protection measures, allowing a compact, low-cost equipment design.

High-frequency circuit technology [PATENT PENDING]*2

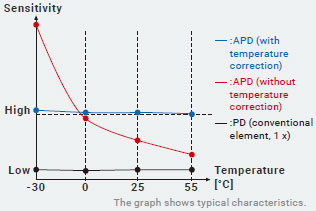

High-sensitivity photo diode controlling algorithm

The sensor has a high-sensitivity APD*3 that can detect even a slight amount of incident light.

With the built-in temperature element that corrects the temperature in real-time, the sensor reduces characteristics variation and ensures stable sensing.

Real-time temperature correction [PATENT PENDING]*2

*2. “PATENT PENDING” means that we applied for a patent in Japan, and “PATENTED” means that we obtained a patent in Japan. (As of September 2024)

*3. APD: Avalanche Photo Diode

2. Equipment free from mutual interference when multiple sensors are used

Automatic Mutual Interference Prevention

The technology adopted by E3AS-HF can prevent interference between the sensors without the need for their channel settings. It prevents the sensors placed to face each other from causing mutual interference, reducing equipment disruptions.

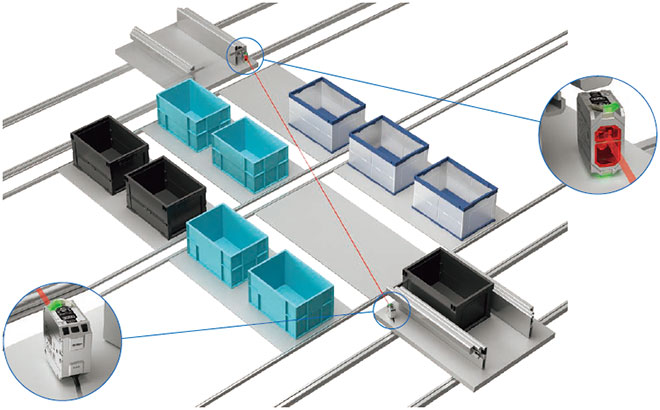

Sensing pallets in an automated warehouse

It is difficult to predict when the sensors on shuttles will encounter each other while many shuttles are running sideways in an automated warehouse. In such a warehouse, unexpected mutual interference inevitably occurs causing the lines to stop. E3AS-HF, however, has an Automatic Mutual Interference Prevention function that can prevent malfunction without the need for channel settings.

Automatic Mutual Interference Prevention

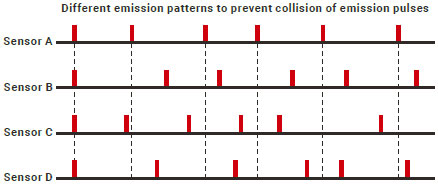

A technology underlying Automatic Mutual Interference Prevention [PATENT PENDING]*1

Sensors have different emission patterns to prevent mutual interference.

If a malfunction still occurs, you can manually modify their patterns.

Image of emission patterns

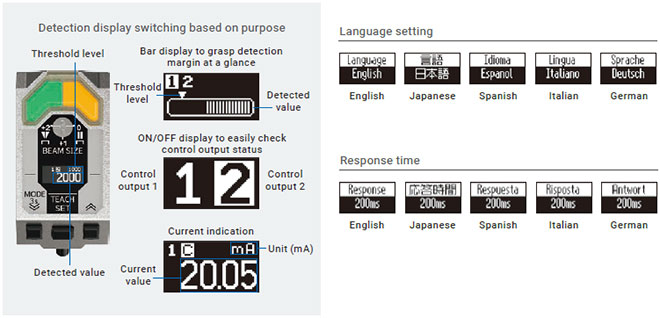

3. An easily visible OLED display

Setup of conventional reflective photoelectric sensors is complicated and requires skills and experience.

However, the enhanced operability of the sensor allows anyone to reliably perform the setup, reducing commissioning hours and ensuring long-term stable operation.

OLED Display with 5 languages supported

A detection display can be selected according to the usage, so you can quickly see the necessary sensor’s status. In addition, the sensor supports five languages for local operators to smoothly set up the units outside Japan.

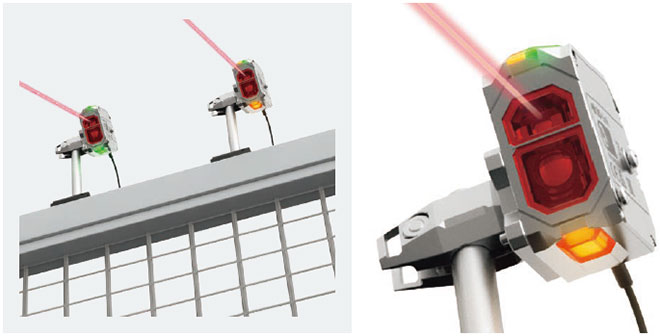

High-brightness indicator at the bottom [PATENT PENDING]*1

The sensor has an indicator at the bottom to help check the operation status of the sensor installed in a high place.

Enhanced visibility with an indicator at the bottom

*1. “PATENT PENDING” means that we applied for a patent in Japan, and “PATENTED” means that we obtained a patent in Japan. (As of September 2024)

Various functions for easy use

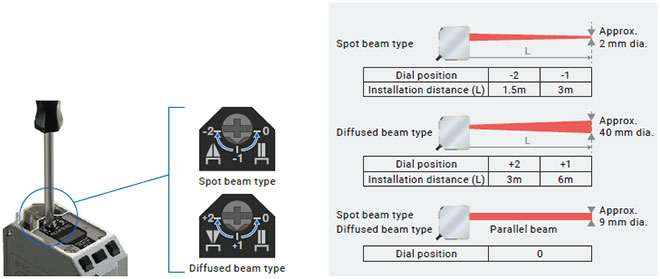

Adjustable spot diameter [PATENT PENDING]*1

The spot diameter adjustable with the dial on the top of the sensor can be selected from three options according to whether you want to detect a spot on a small workpiece such as a pin or an area on a surface such as a hole.

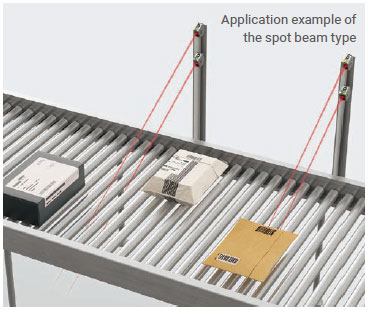

Detecting workpieces on a roller conveyor

The spot diameter can be reduced to approximately 2 mm. Set up the optical axes so that they pass between the rollers to stably detect workpieces only.

Detecting workpieces with the spot beam type

Detecting how many pallets are remaining

The spot diameter can be increased to approximately 40 mm, allowing stable detection regardless of the shape and holes of the pallets.

Sensing pallets with the diffused beam type

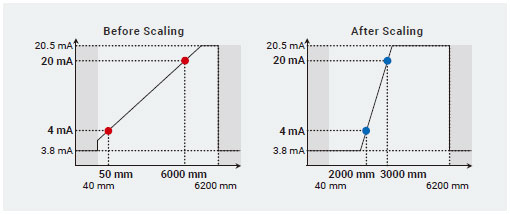

Scaling function

Converts a digital output value (distance) to a given output current value. Use the function when you use a narrow sensing distance range. The scaling function helps you find even small changes.

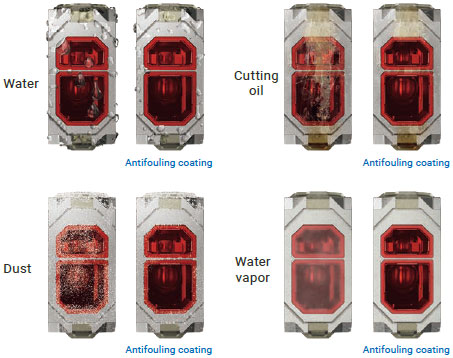

Antifouling coating [PATENTED]*1

A dirty sensing surface can cause false detection due to the principle of photoelectric sensors. The antifouling coating on the sensing surface prevents paper dust, etc. from sticking to the sensing surface, and keeps the lens from fogging as well. Adding an air blow unit available as an accessory can help further reduce the frequency of cleaning the sensor.

Air blow unit [PATENTED]*1

Attaching an air blow unit helps greatly reduce the frequency of false detection since it prevents contamination of the sensing surface of the sensor installed in a high, difficult-to-clean place.

Environmentally-resistant structural design

Highly resistant to water, oil, and high-pressure washing and can be used in a harsh environment.

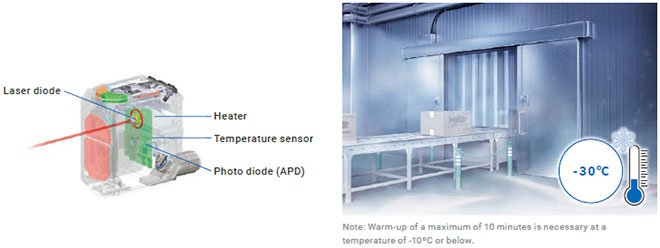

Operable at an ambient operating temperature of -30ºC

With a combination of a heater and a temperature sensor built in to control operation, the sensor can reliably operate in a low-temperature environment such as a freezer warehouse.

*1. “PATENT PENDING” means that we applied for a patent in Japan, and “PATENTED” means that we obtained a patent in Japan. (As of September 2024)

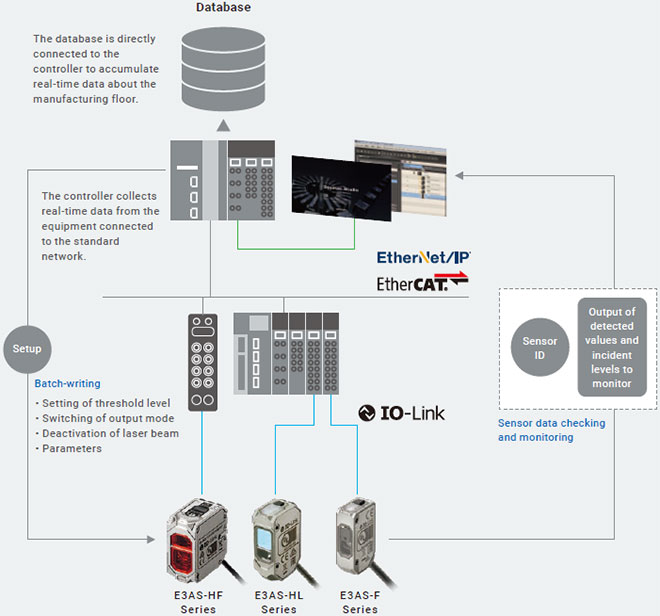

IO-Link supported as standard to visualize a manufacturing environment

In addition to ON/OFF signals, IO-Link can send and receive the sensor information to and from an upper-level controller. This allows real-time status monitoring of the sensors, reduction of the configuration hours during setup and replacement, and reduction of unexpected equipment disruptions due to accidental problems.

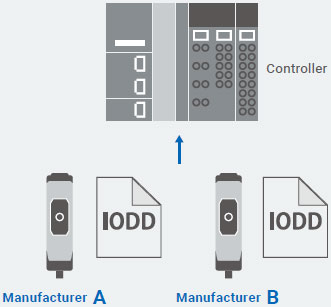

Open international standard

IO-Link is an open information technology (interface) used between a sensor/actuator and an I/O terminal, as defined in IEC61131-9, an international standard.

Globally deployable

Every IO-Link sensor has an IODD (IO Data Description) file containing information about what kind of equipment it is and what parameter settings it needs. The specification of IODD file is globally common and shareable by all IO-Link sensors regardless of their manufacturers.

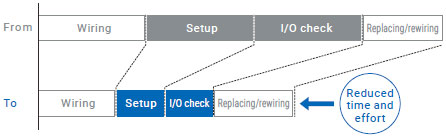

Line commissioning and maintenance with less people in less time with IO-Link

With IO-Link, reduce commissioning time by batch-setting the sensors and cut troubleshooting time during mass production by utilizing field data.

Reduce commissioning time by batch-writing settings from IO-Link device configuration tool

Setting information can be batch-written to thousands of sensors on a line, effectively reducing commissioning time and inconsistent settings.

Predictive monitoring and quick recovery by checking and monitoring sensor data

The monitor shows light intensity decrease due to sensing surface contamination or other reason, allowing users to take proactive actions to prevent potential false detections. This reduces the frequency of unexpected failures.

Converting the equipment information into meaningful data with IO-Link

• EtherCAT® is a registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

• EtherNet/IP™ is a trademark of ODVA.

• QR code is the registered trademark of DENSO WAVE.

• Ecolab and its logo are registered trademarks of Ecolab USA Inc.

• Smartclick is a trademark or registered trademark of OMRON Corporation in Japan and other countries.

• Other company names and product names in this document are the trademarks or registered trademarks of their respective companies.

• The product photographs and figures that are used in this catalog may vary somewhat from the actual products.

Spot beam type

| Connection method | Model | |||

|---|---|---|---|---|

| Sensing distance (Red light) |

Output | NPN output | PNP output | |

| IO-Link baud rate |

--- | COM3 (230.4 kbps) | ||

| Pre-wired (2 m) *1 |  |

E3AS-HF6000SMN 2M | E3AS-HF6000SMT 2M | |

| M12 Connector (horizontal) | E3AS-HF6000SMN M1H | E3AS-HF6000SMT M1H | ||

| M12 Connector (vertical) | E3AS-HF6000SMN M1V | E3AS-HF6000SMT M1V | ||

| M12 Pre-wired Smartclick Connector (0.3 m) |

E3AS-HF6000SMN-M1TJ 0.3M | E3AS-HF6000SMT-M1TJ 0.3M | ||

Diffused beam type

| Connection method | Model | |||

|---|---|---|---|---|

| Sensing distance (Red light) |

Output | NPN output | PNP output | |

| IO-Link baud rate |

--- | COM3 (230.4 kbps) | ||

| Pre-wired (2 m) *1 |  |

E3AS-HF6000DMN 2M | E3AS-HF6000DMT 2M | |

| M12 Connector (horizontal) |

E3AS-HF6000DMN M1H | E3AS-HF6000DMT M1H | ||

| M12 Connector (vertical) |

E3AS-HF6000DMN M1V | E3AS-HF6000DMT M1V | ||

| M12 Pre-wired Smartclick Connector (0.3 m) |

E3AS-HF6000DMN-M1TJ 0.3M | E3AS-HF6000DMT-M1TJ 0.3M | ||

*1. Models with 5-m cable length are also available with “5M” suffix. (Example: E3AS-HF6000SMN 5M)

Accessories (Sold Separately)

Sensor I/O Connectors (Sockets on One Cable End)

(Models for Connectors / Pre-wired Connectors)

A Sensor I/O Connector is not provided with the Sensor. It must be ordered separately as required.

Round Water-resistant Connectors XS5 serie

| Appearance | Cable specification | Cable diameter (mm) |

Cable connection direction |

Cable length (m) | Sensor I/O Connector model number |

|---|---|---|---|---|---|

| M12 Smartclick Connector Straight type  Right-angle type  |

PVC robot cable | 6 dia. | Straight | 2 | XS5F-D421-D80-F |

| 5 | XS5F-D421-G80-F | ||||

| Right-angle | 2 | XS5F-D422-D80-F | |||

| 5 | XS5F-D422-G80-F |

Round Water-resistant Connectors XS2 serie

| Appearance | Cable specification | Cable diameter (mm) |

Cable connection direction |

Cable length (m) | Sensor I/O Connector model number |

|---|---|---|---|---|---|

| M12 Screw Connector Straight type  Right-angle type  |

PVC robot cable | 6 dia. | Straight | 2 | XS2F-D421-D80-F |

| 5 | XS2F-D421-G80-F | ||||

| Right-angle | 2 | XS2F-D422-D80-F | |||

| 5 | XS2F-D422-G80-F |

Note: 1. The XS5W/XS2W (Socket and Plug on Cable Ends) are also available. Refer to XS5/XS2 on your OMRON website for details.

2. The connectors will not rotate after they are connected.

3. The cable is fixed at an angle of 180° from the sensor emitter/receiver surface.

Mounting Brackets

For E3AS-HF series

A Mounting Bracket is not enclosed with the Sensor. Order a Mounting Bracket separately if required.

| Appearance | Model | Pre-wired | M12 Pre-wired Smartclick Connector |

M12 Connector (horizontal) |

M12 Connector (vertical) |

|

|---|---|---|---|---|---|---|

| L-shaped Mounting Bracket (180°) |

|

E39-L245 | Yes | Yes | Yes | --- |

| L-shaped Mounting Bracket (360°) |

|

E39-L255 | Yes | Yes | Yes | --- |

| Flexible Mounting Bracket *1 |

|

E39-L264 | Yes | Yes | Yes | Yes |

| Post 50 mm |  |

E39-L262 | Yes | Yes | Yes | --- |

| Post 100 mm |  |

E39-L263 | Yes | Yes | Yes | Yes |

| Air Blow Unit *2, *3 |

|

E39-E17 | Yes | Yes | Yes | Yes |

| Front Protection Cover |

|

E39-E20 | Yes | Yes | Yes | Yes |

*1. The Flexible Mounting Bracket is not provided with a Post (E39-L262/E39-L263). It must be ordered separately.

*2. When using the Air Blow Unit (E39-E17), use the L-shaped Mounting Bracket (E39-L245).

*3. The tube for air is not included.

| Sensing method | TOF (Time of flight) | ||

|---|---|---|---|

| Model | Type | Spot beam type | Diffused beam type |

| NPN Output | E3AS-HF6000SMN[] | E3AS-HF6000DMN[] | |

| PNP Output | E3AS-HF6000SMT[] | E3AS-HF6000DMT[] | |

| Sensing distance | 50 to 6,000 mm | ||

| Beam size | Variable (Parallel / Spot) | Variable (Parallel / Diffusion, used with 40 dia. or less) | |

| Light source (wavelength) | Red laser (660 nm) | ||

| Power supply voltage | 10 to 30 VDC, (including ripple (p-p) 10%), Class2 | ||

| Consumption current *1 | 65 mA max. (when power voltage is 24 V), 155 mA max. (when power voltage is 10 V). Note: 125 max. at environment below the freezing point (when power voltage is 24 V) |

||

| Control output | Load power supply voltage 10 to 30 VDC (Class2), Load current 100 mA max. each output (total of 2 outputs is 200 mA max.) Residual voltage (Load current 10 mA max.: 1 VDC max., Load current 10 to 100 mA: 2 VDC max.) Open collector output type (Depends on the NPN/PNP output type) NO/ NC selectable |

||

| Current output | 4 to 20 mA, maximum load resistance 500 Ω | ||

| External input | Laser OFF / Teaching / Zero reset selectable NPN ON time: 0 V short-circuit or 1.5 V or less (Outflow current: 1 mA or less) OFF time: Power supply voltage short-circuit or open PNP ON time: Power supply voltage short-circuit or within power supply voltage - 1.5 V (Sink current: 1 mA or less) OFF time: 0 V short-circuit or open |

||

| Protection circuits | Reversed power polarity protection, Output short-circuit protection and Output reverse polarity protection | ||

| Indicator | OLED Display (White), Power/Communication indicator (Green), Operation indicator (Orange), and Bottom indicator (Green, Orange) | ||

| Response time | 2 ms / 10 ms / 50 ms / 200 ms selectable | ||

| Mutual interference prevention | Auto setting (Manual setting is also possible: up to 4 units) | ||

| Ambient illumination | Incandescent lamp / Sunlight: 100,000 lx max. | ||

| Ambient temperature | Operating: -30 to 55°C (with no icing or condensation) *2, Storage: -30 to 70°C (with no icing or condensation) |

||

| Ambient humidity | Operating: 35 to 85%, Storage: 35 to 95%RH (with no condensation) | ||

| Insulation resistance | 20 MΩ min. at 500 VDC | ||

| Dielectric strength | 1,000 VAC at 50 / 60 Hz for 1 min | ||

| Vibration resistance | 10 to 55 Hz, 1.5-mm double amplitude for 2 hours each in X, Y, and Z directions | ||

| Shock resistance | 500 m/s2 for 3 times each in X, Y, and Z directions | ||

| Enclosure ratings | IP67 (IEC60529), IP69K (ISO20653), IP67G (JIS C 0920 Annex 1) *3 | ||

| Weight (packed state/Sensor only) |

Pre-wired (2 m) | Approx. 280 g/approx. 167 g | |

| M12 Connector (horizontal/vertical) |

Approx. 223 g/approx. 114 g | ||

| M12 Pre-wired Smartclick Connector (0.3 m) |

Approx. 237 g/approx. 128 g | ||

| Material | Case | Aluminum die cast (Chrome plating) | |

| Cover | SUS304 | ||

| Indicator | Polyethersulfone (PES) | ||

| Lens cover and Display |

Methacrylic resin (PMMA), Antifouling coating (Lens cover) | ||

| IO-Link Communication specifications | IO-Link specification |

Ver. 1.1 | |

| Baud rate | COM3: 230.4 kbps | ||

| Data length | PD size: 4 bytes, OD size: 2 byte (M-sequence type: TYPE_2_V) | ||

| Minimum cycle time |

COM3: 1.2 ms | ||

| Device profile | Smart Sensor Profile (SSP4.1.1) Identification and Diagnosis (I&D) |

||

| Conformity standards | UL/CSA Certification, CE Marking, RCM, UKCA, Various laser standards *4, Ecolab, RoHs2, WEEE2 | ||

| MTTFd | 340 year | ||

| Accessories | Instruction manual, compliance sheet, index list (attached for IO-Link type only), FDA certification label Note: Mounting Brackets must be ordered separately. |

||

Note: 1. Altitude: Up to 2000 m, Pollution degree: 3, Enclosure type: Type1.

*1. Excluding load current.

*2. When the product is used in an environment with a temperature of -10°C or less, a warm-up time (10 min maximum) is required.

*3. JIS C 0920 Annex 1 describes the IP67G rating oil and the oil resistance of the product has been assessed by the document.

Please visit the website of the Japanese Industrial Standards for more informarion. (https://www.jisc.go.jp/index.html)

*4. For details, refer to the To safely use laser products on Catalog.

(單位:mm)

Sensors

Pre-wired Models/Pre-wired Connector Models

E3AS-HF6000[] (-M1TJ)

M12 Connector (horizontal)

E3AS-HF6000[] M1H

M12 Connector (vertical)

E3AS-HF6000[] M1V

Accessories (Sold Separately)

Mounting Brackets

E39-L245

Material: Stainless steel (SUS304)

*1. Accessories

2-M3-L35 Cross Recessed Pan Head Screws (Attached to SW+JIS W)

Material: Stainless steel (SUSXM7)

E39-L255

Material: Stainless steel (SUS304)

*1. Accessories

2-M3-L35 Cross Recessed Pan Head Screws (Attached to SW+JIS W)

Material: Stainless steel (SUSXM7)

Flexible Mounting Bracket

E39-L264

Post

50 mm

E39-L262

Material: Stainless steel (SUS304)

100 mm

E39-L263

Material: Stainless steel (SUS304)

Air Blow Unit

E39-E17

Front Protection Cover

E39-E20

中文

| 型錄名稱 | 型錄編號 [容量] |

更新日期 | |

|---|---|---|---|

| SCEB-094C-TW5-01 [3703KB] |

2025年8月5日

20250805

|

E3AS-HF 系列型錄 |

English

Global Edition

| Catalog Name | Catalog Number [size] |

Last Update | |

|---|---|---|---|

| E626-E1-04 [8605KB] |

Jun 02, 2025

20250602

|

E3AS-HF Series Catalog |

誠睿台南所 TEL:06-2493086

誠睿台中所 TEL:04-23380790

誠睿新竹所 TEL:03-6685558

客服信箱 service@hitifa.com.tw

誠睿台南所 TEL:06-2493086

誠睿台中所 TEL:04-23380790

誠睿新竹所 TEL:03-6685558

客服信箱 service@hitifa.com.tw